Test & inspection

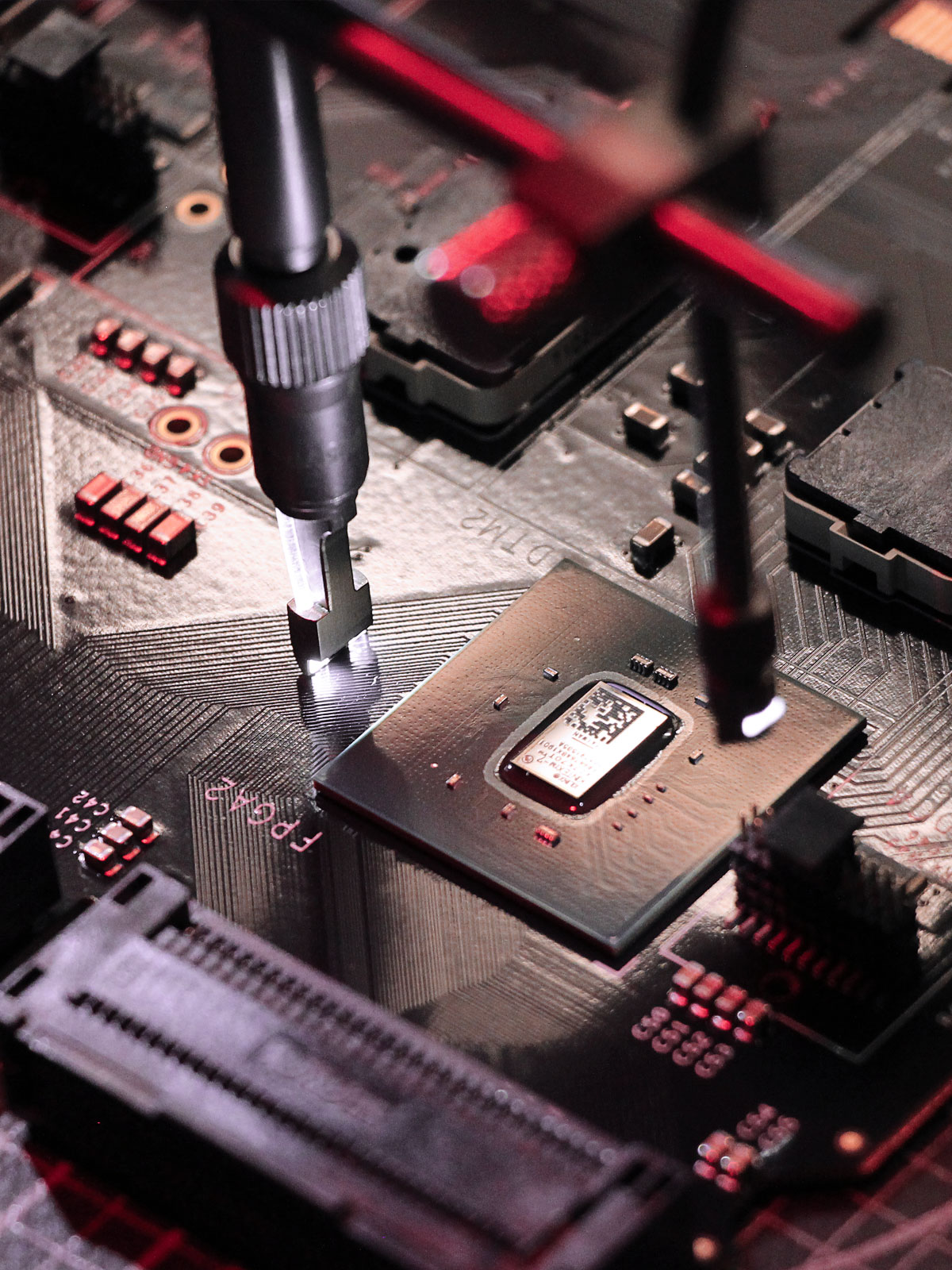

Testing solutions

Whether you have a simple small outline package or a high-end BGA, we’ve got a test solution for you.

- Seica Pilot LX (off-site)

- 4 Independent flying probes

- Functional test

- Optical inspection

- On-board programming

- Vectorless test

- Boundary scan

- Advanced connection test

- Flexible, high level test description language

- Device-centric approach

- Testing and programming non-JTAG devices

- Bespoke functional testing tailored to product application

- Utilising customer supplied or in-house produced test equipment

- Votsch 7027-20 environmental stress screening oven

- Temperature and humidity cycling

- Temperature range +180°C to -70°C

- Maximum rate of change 20°C per minute

Test & inspection

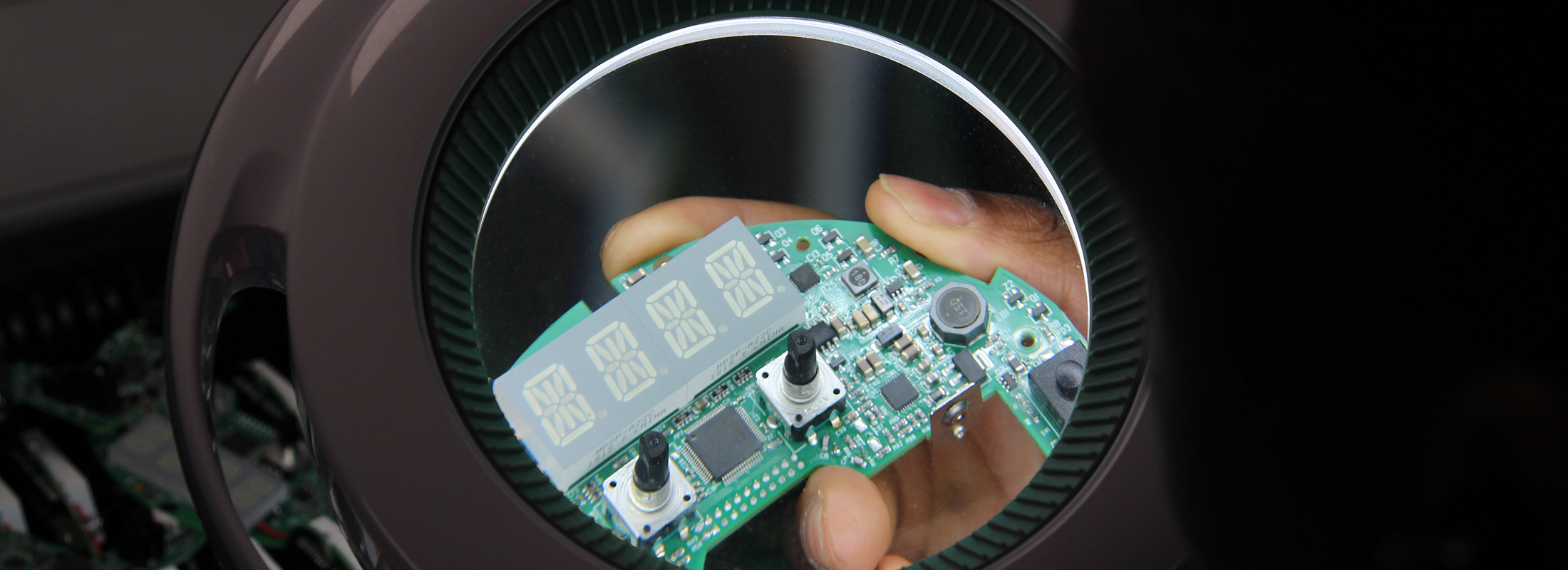

Visual inspection

Every assembly we produce is 100% visually inspected to the internationally recognised IPC standard by highly experienced and qualified staff.

BGA inspection/rework

ERSA Scope 2 Plus

The World’s best optical inspection system for BGA, flip chip and CSP

Metal Halide light source, fibre optic light brush and fan

High Resolution BGA optical lens, wide angle and flip chip lens

ERSA IR550A

3rd generation BGA rework centre

Live video image

Automated optical inspection

Mirtec MV3L

5 camera system: 1 top down, 4 side angle

4 Mega pixel top, 2 mega pixel side angle

Height measuring laser for co-planarity

ALeader ALD625 Proi3D offline AOI

I3D technology, 4M pixel high speed camera

Shadow free , FAI, SPC barcode reader

2D solder paste inspection, wave soldering inspection

X-Ray inspection system

Unicomp AX-8200HR Si3D X-Ray inspection system

90KV X-Ray System

Digital camera 450× magnification

140° tilt range, Si3D images, step and repeat programming

90KV X-Ray System

Digital camera 450× magnification

140° tilt range, Si3D images, step and repeat programming

Do you need to deliver quality products?

A full team of trained technical support is available to answer your queries from 8:30 to 17:00 / Monday – Friday

+44 (0)1245 325252